Electronics Industry

Electronics Industry

Electronics has been playing a pivotal role in driving continuous innovation and fostering seamless connectivity, shaping a highly efficient and interconnected world. In a whirlwind of constant technological advancements, the electronics industry has been rapidly evolving, fueling innovations like IoT, AI, and 5G, while miniaturization, enhanced connectivity, and improved efficiency have been instrumental in shaping its growth and revolutionizing diverse sectors.

Blue Star E&E excels in meeting the electronics industry’s demands with its advanced testing solutions. Their offerings include dependable quality inspection at high throughput speeds, comprehensive testing of components, sub-systems, and systems pre-assembly and during repairs, and automated assembly lines for fast yet top-notch production of electronic products. With these state-of-the-art PCB solutions, electronics manufacturers can ensure product reliability, safety, and efficiency, fostering continuous innovation and meeting the ever-growing consumer demands in the dynamic electronics market.

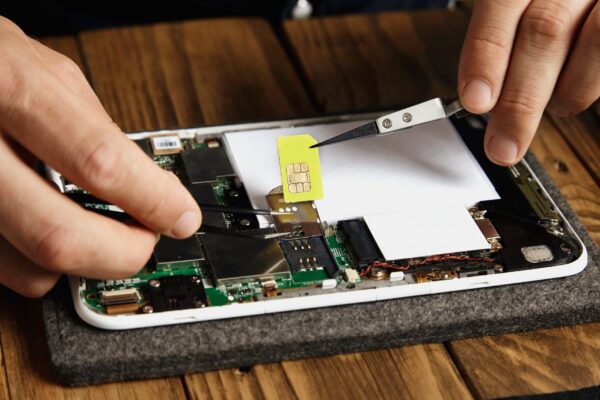

PCBs are the backbone of electronic gadgets, facilitating seamless communication between components in smartphones, tablets, computers, and laptops. In consumer electronics and appliances like televisions and home appliances, PCBs connect essential circuits for smooth functioning and efficient energy management. Their versatility and reliability make PCBs vital for a wide range of electronic devices and appliances across industries.

Blue Star E&E acknowledges the industry’s requirements. By analyzing specific challenges, we deliver customized and innovative solutions that precisely meet our customers’ unique demands, ensuring superior value and excellence in our products and services.

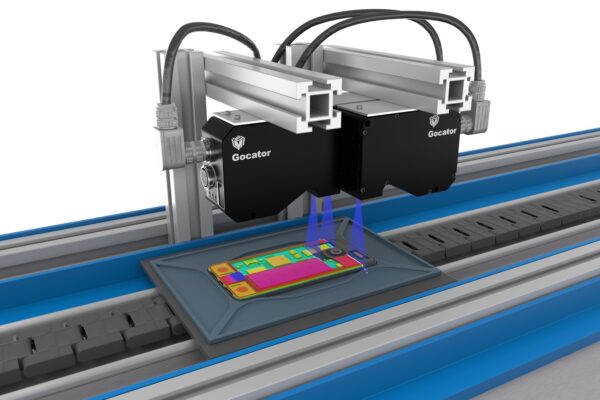

Utmost precision is demanded in the manufacture of consumer electronics products, such as mobile phones, tablets and displays. The interplay of a wide variety of materials and the complex geometries of these products are the key quality assurance challenges. 3D Metrology helps the consumer electronics industry to master these challenges.

Blue Star E&E’s non-contact optical sensors, for example, help you measure the gap between the glass and the housing of a smartphone, check the flatness of a display glass, or inspect step heights, edges and PCB coatings, all to within a few micrometres.

In mass production lines in the consumer electronics industry, it is not just high precision and speed that are required of optical sensors but also the ability to take inline measurements. Blue Star E&E’s 3D Sensors are used in the electronics industry for inline inspection of many components including glue beads, cell phone display glass assemblies, cell phone batteries, SIM card connector pins, cell phone housing, the presence-or-absence check for parts on circuit boards, circuit board assemblies, etc.

In the rapidly evolving electronics industry, efficient warehouse management is crucial to meet the demands of consumers for the latest gadgets and devices.

From component storage to order fulfillment, our end-to-end automation solutions are designed to streamline every aspect of the warehouse workflow. With advanced conveying systems, robotic picking and packing technologies, and intelligent inventory management software, we empower electronics companies to maximize efficiency and accuracy in their warehouse operations. Moreover, our Automatic Guided Vehicles (AGVs) and Automated Storage and Retrieval Systems (AS/RS) ensure seamless movement and storage of electronic components and finished products, reducing reliance on manual labor and minimizing the risk of errors.

By partnering with Blue Star Industrial Solutions, electronics companies can achieve greater agility, scalability, and cost-effectiveness in their warehouse operations.